#1 Getting Started -sorting armor and getting supplies

#2 The Corset and Butt Plate

#3 Torso and Shoulder Pieces

#4 Upper Arm Pieces and Shoulder Bells

#5 Lower Arm Pieces and Hands

#6 Leg Pieces

#7 Belt and Ammo Boxes, and detonator

#8 Helmet

After working on my upper arms, its now time to do the lower arm pieces and the gloves.

Materials for these steps:

Glue e6000

Lexan Scissors

Self-healing craft cutting mat

Utility knife (uses razor blades) or box cutter

Spare sheet of ABS included in kit

Two Spare cloth scraps or old t-shirts for wiping extra glue and ABS dust from sanding

Protective Breathing Mask

Cutting gloves from hardware store

Metal ruler that bends

Small clamps - you pick the kind

Strong magnets or rare-earth magnets

Blue Painters tape

Dremel with sanding burr or sand paper, both medium and fine grit

Craft foam for inside of arms

Marker

Pencil

Note: I assume you have already read over my Upper Arm Tutorial - if not, please do so!

Lower Arms

The lower arm piece has one overlapping seam on outside (which is raised and its about one inch wide) and the inside seam is a butt joint.

The trick is to trim your seams in a straight line so they match up nicely. My arms came labeled as A and B. Those labeled A go over B ones in the overlapping edge. But if nicely trimmed, there will be no need for the dreaded ABS Paste of Doom - that method requires hours of sanding to make it smooth. (ABS Paste is used to fill in cracks to make the two pieces look seamless, but we do want a seam, just a nice one)

1. Trim and Sanding Edges:

I begin trimming extra plastic off of edges, just for initial fitting. Sand after you are sure they are going to fit.

This is the raised edge that will overlap the other side. The side marked A will be on top or outside, and the piece marked B will be on bottom or inside.

Note how crooked it is untrimmed. Easy to fix, take your metal ruler and mark the few area that need sanding with a pencil and sand off. The metal ruler is ideal because it bends. One trick is to use clamps to hold the metal ruler against the curves in the plastic. This piece needs no trimming for initial test fit though, this can be done later :)

The wonky ridge here gets trimmed off. As you can see in image below from trimming upper arms, use your ruler and a sharpened pencil to mark a straight line. Then trim. Sand or smooth out the edge with your dremel. Be careful, you can sand too much and create a gap.

As you can see below, the edges go straight together. And I did a pretty good job on making the lines straight. The way to glue this is to make a butt joint. Sand edges to be glued just a bit to smooth them out. Wipe off all small particles. Other edges can be sanded now or later. It is easier to sand before you glue them. Label them A1 and B1, and A2 and B2 on inside so you don't mix them up after you sand them to fit together!

2. Tape and test fit pieces:

Just like the legs, you really DO have to tape them together with blue painters tape and make sure they fit. Otherwise, you won't be able to get your hand through the opening. And test it wearing your black undershirt and gloves!

Now, I didn't take a pic of the taped-up test fit. I took one while trimming. But I almost thought the arm was too long. That means trimming off the wrist, and using a heat gun to reform the returned edge. If I didn't do that I would lose mobility or bendability of my arm. I was given some good advice to trim the elbow area on the inside by 0.75 inches to allow it to bend more.

So I did, and it will allow me to bend my elbow almost to my chest. Very important if you want to be able to put your own helmet on. It looks deeper in the picture but its only three-quarters of an inch. I promise!

3. Glue together with a strip of ABS

I created a short video on how to score and snap ABS sheets to create your strips or snap plates. View the video here.

I cut my strip about 3/4 of an inch and glued it on with e6000. I ran my sanding burr from my dremel over the edge of my ABS strip just to give it a softer edge. Wipe off the pieces first to remove any ABS dust from sanding. The e6000 did ooze out a bit and I wiped it off with my old t-shirt rags as I went. You only need a thin line.

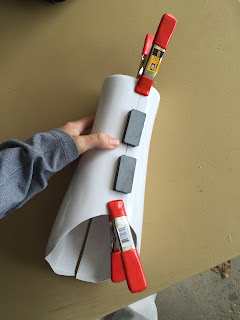

Then clamp the pieces together so they cure properly. Let cure for 24 hours or so. Be careful none of the clamps are touching oozed out glue, or they will be glued as well. It is very helpful to have an extra set of hands here so one person can hold one end while you work on the other.

And the next day its all set and ready for the other side.

Remember that any glue that dries can be easily scratched off with your fingernail, so globs can be removed once its dry. Any glue globs left in the crease will also keep you from getting a tight line, so remove as much as you can prior to glueing on the second piece.

Obviously the more clamps you have, the faster this will go. I purchased ten clamps so gluing two pieces at a time is what I did. And it takes about an hour to sand and glue. So an hour each day to work on pieces worked with my schedule.

After the strip dried, the next day I glued on the other half. I used magnets to hold the middle in. They left smudges!

So, I bought Novus Polish to remove smudges, and later learned a trip. Cover the magnets in painters tape.

So, don't be like me. Cover your magnets with painters tape first.

Clamp and let dry.

I found that keeping my magnets in pairs was useful. Then you just pull apart and put in. Aligning them can cause pinching.

Let dry. Clean off smudges if you didn't tape your magnets :)

Note mine had a gap. No worries!

Fill it with caulk and it will look great.

I would tape and fit test this again - just to be sure.

I found that with my gloves on I couldn't get my hand through the wrist opening. So I had to open that area a bit more. Than means my edge didn't go straight down the arm. But wonky it is, and wonky is ok!

I marked with a pencil where the edge should be.

Put a line of e6000 glue, line up with pencil marks, and clamp down to dry. Again, I used magnets for the middle (tape them up, remember)

Let dry for 24 hours.

4. Cleaning up edges

When done, note that some edge are crappy. You will need to trim and sand them down. I used my scissors to cut them straight and then sanded them.

One edge actually bent up, not in. I used a heat gun to bend in (boiling water would work too) but found it caused a slight separation along the seam.

So I cut them and sanded them too. At least it didn't bend out. And in doing so I removed quite a bit of the return edge near the seam. It happens.

The overlapping joint needs trimming too, other wise it will cut into your skin.

When done, fill cracks with caulk. The one on the left is caulked and the other is not. It makes a big difference!

Now, I have heard of people using bondo. But then you have to paint. And I know I said seamless somewhere before, but actually there is supposed to be a slight seam. Just not a raised seam.

5. Glue in foam

Just so you know, a strip of foam on the inside is what will hold it in place.

I had some green foam in my house, and tried using that. Worked great for holding it in place. But a tall person could see the green. If they looked down the arm piece. (it flares out so its possible)

So I went and got white. I used a 1 inch wide strip about 4 inches long. Glue it in on inside however you feel it helps. And viola! These pieces are done!

Gloves

1. Buy recommended gloves

I got the Nomex gloves from amazon. I love them!

2. Trim and sand your hand plates

Mine were already pretty trimmed. I just sanded them down and make the lines look a little better.

3. Attach Velcro to pieces and gloves

This is super easy but I managed to mess it up anyway. So read on, and learn from my mistakes.

First, lay out your gloves and pieces together. This prevents you from putting the wrong pieces on wrong hands.

Next, cut your velcro pieces to fit inside hand plates, and cut matching pieces for gloves.

First mistake, I cut the velcro pieces too big. They fit just inside the plates, but actually show on the gloves. So, cut them smaller and it will not show as much.

Peel off the backing and stick the velcro side to your hand plates.

Second mistake: I put the soft velcro on the hand plates. That meant the scratchy velcro was on the glove. When you put on your lower arm piece, it tears up the foam inside. So, switch them. Put the softer piece on the glove, and scratchy piece on the hand plate.

Now, here is the trick. Put the matching velcro face down on the hand plate. Peel off the backing and then stick the whole piece on your glove the way it is supposed to be.

Press it down, and carefully separate. Or leave for 24 hours so the glue cures.

And your done!

My hand pieces are a little too large, so I will be looking at latex options in the future. If you trim them and remove the return edge, the velcro will show. Just FYI.

And your lower arms are done!

When getting dressed, your hand plates remove so you can put your gloves on first, then your lower arm pieces, then your hand plates.

#1 Getting Started -sorting armor and getting supplies

#2 The Corset and Butt Plate

#3 Torso and Shoulder Pieces

#4 Upper Arm Pieces and Shoulder Bells

#5 Lower Arm Pieces and Hands

#6 Leg Pieces

#7 Belt and Ammo Boxes, and detonator

#8 Helmet

No comments:

Post a Comment